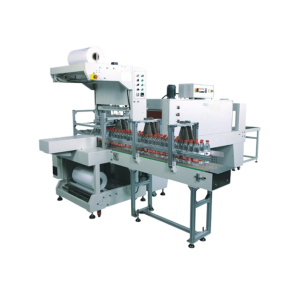

Specification:

Adopts

world advance components, stable and durable.

Sealing

cutter is specially designed, Sealing line is firm, without cracking, and

without sticking to the knife;

Automatic

feeding, iteming, product pushing, film feeding and sealing;

Non-polar

mechanical speed adjustment, adjust speed of feeding conveyor;

It can

package several sets without tray in row 2, row3 and row4 according to

requirement. It can replace the packing way via changeover switch on control

panple;

Operation

is easy and simple. It only takes 2-3 minutes to change different type;

According

to different bottle shape, design automatic feeding device;

Direction

of feeding conveyor can be based on customer needs, to be left or right

feeding;

Suitable

for PE shrink film.

Technical Parameters:

|

Model |

WWP-6030T |

WWP -6040 |

|

Packing speed |

6-14 pcs /min |

20~80pcs/min |

|

Packing size( W+H ) |

≤ 700mm |

L1500×W650×H330mm |

|

Cutter size/ tunnel size |

700mm |

L1800×W600×H400mm |

|

Power |

2 KW |

22KW |

|

Power supply |

3∮,220/380V,

50/60Hz |

3∮,220/380V, 50/ 60Hz |

|

Max current |

10A |

35A |

|

Air pressure |

6 kg/cm³ |

/ |

|

Machine size |

L1360×W2120×H1900mm |

L2700×W900×H1640mm |

|

Machine weight |

465kg |

400kg |

Standard components:

WWP-6030T

Motor: Taiwan ZD

Frequency converters: Japan Panasonic

PLC: Japan Omron

Time relay:Japan Omron

Temperature controller:Japan Omron

Sensor: Germany Sick/ American Banner

Cylinder: Taiwan Shako/ AirTac

WWP-6040:

Air machine: China Tianyang

Conveyor motor: China GPG

Frequency changer: China DONGYUAN

Temperature controller: Japan Omron

Cam switch: China Taiwan Tiande

Reply: France Schneider

Ac contactor: China CHINT